|

||||||||

|

|

||||||||

|

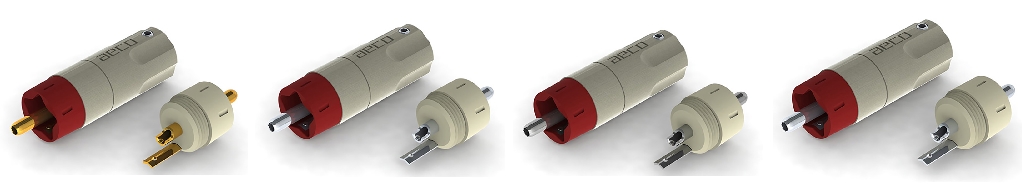

RCA / PHONO CONNECTORS We stock a large range of RCA connectors that can be available with our cables. You are welcome to choose these connectors based on prior experience you may have, on recommendations and reviews, or based on their materials, their design, your budget etc. From our side, we are happy to offer our recommendations, but these will be based on technical assessments of the individual connectors, rather than on a perception of “how they sound”. It goes without saying that RCA plugs (and electrical connectors in general) cannot be evaluated the same way as cables or wires - by simply analyzing their electrical properties and the impedances that result from their abstract design. Their role as mechanical structures is vital to their performance (and the performance of the system as a whole) and their assessment cannot be reduced to the conductivity of their materials. Furthermore, unlike the insulated conductors / wires of a cable, the exposed metals that are used on electrical contacts WILL react chemically to the environmental conditions. So please do keep these factors in mind when weighting the benefits and drawbacks of the individual connector designs and do not simply assume that a connector will perform better by simply being made of pure copper or pure silver. Also, a higher price is not always an indication of better performance. In this section, we attempt a small introduction and a brief assessment of various RCA connectors that we have chosen to use on our cables.

This type of connector is still the industry standard for singled ended / unbalanced audio connections in Hi-Fi applications. RCAs come in many variations but their core design has remained largely unchanged since they first appeared in the 1940s. The interface of all standard RCA plugs features a central pin conductor (signal) and a metal collar (signal ground). These two contacts are separated by an insulator while the body of the connector can be a metal extension of the ground collar, an isolated metal structure or simply a plastic support structure. RCA connectors can also feature a metal or plastic outer sleeve which can offer additional support and protection (and is some cases it provides EMI/RFI Shielding). Despite its popularity and widespread use, the RCA connector is far from an ideal option for applications that deal with low level, analogue audio signal (phono and line level). Its conductors have a very high mass, disproportional to the requirements of the current it handles and the connector's shape and geometry result to unfavorable, capacitive and inductive properties. However, some significant alterations to the classic deign took place during the last 25 years that gave new momentum to the RCA connector and made it far more relevant and suitable for analogue Hi-Fi applications. Neutrik Rean NYS373: In our opinion, this is the best low cost RCA option. These connectors have a slim and long profile; they feature gold plated contacts and a rubber boot for strain relief. Neutrik have made a significant improvement on them over the past few years that may not be particularly obvious. The ground contacts -made of a higher than average quality brass (H62) - have adopted a very effective profile in order to minimize the contact resistance by adjusting to the small tolerance variations of the RCA sockets. The thinner ground contacts have the ability of slight expansion and retraction. The ground collar is slotted with 2 of the plate parts skewed inwards, in order deliver a spring-like effect and ensure that they neither cause wear to the socket nor have a loose fit. This may appear like a small detail but given the importance of contact resistance and the mechanical factors that determine it (in the context of tolerance variations of the RCA sockets and over a period of time / mating cycles) this feature helps such a modest connector outperform plugs that have luxurious presentations and far higher price tags. Although these Neutrik Rean RCAs are very basic connectors, they have become an industry standard and we strongly believe that in such a price range they cannot be matched by other alternatives. No, we would not describe them as audiophile connectors but they are much better performers than many luxury RCAs that one can find fitted on many “audiophile” cables.

Neutrik Profi: These heavy duty phono plugs are mostly known for their retractable, spring loaded ground collar. A feature which allows them to ensure that ground contact comes before the signal/hot contact, preventing any damage to the equipment during “hot” cable swapping. The ground contacts of the Profi plugs will also offer a very firm grip on the RCA sockets

Switchcraft 3502A: This is a US manufactured connector, very popular among users of vintage audio equipment. Minimal & durable construction. It features a solid, nickel plated copper alloy pin. This is the most popular version of the connector. However a gold plated version is also available (3502ABU) as well as a nickel one with smaller profile (3502). We are not particularly keen on nickel plated connectors, however, if your equipment already use nickel sockets and you are familiar and satisfied with Swithcraft RCAs, they are a very good choice of connectors.

Deltron 332 / 330: Deltron is one of the oldest and most well known British manufactures, designing and producing audio connectors since 1946. Deltron RCA connectors are manufactured in the UK from turned brass. The 332 version features a hollow central pin and a patented T-slot ground contact which allows maximum contact even on undersized phono sockets. The connector is finished with a flash gold plating (nickel free). The 330 version features a silver plated central pin and nickel outer shell. Their very small profile is ideal for use on equipment where space is limited. Overall, a very well machined, classic RCA connector.

We do stock a large variety of “classic type” RCA connectors. However, despite their low cost, we consider the above offerings by Neutrik Rean, Deltron and Switchcraft to be some of the best performing options. Their design and choice of materials show a very good understanding of the real priorities for a reliable connection and they have proven themselves over the many decades in both the pro-audio and the consumer electronics industry. They do not aim at impressing with their appearance, nor with constant references to high purity materials

The locking barrel was the first, major innovation that occurred on the RCA design. It effectively deals with the most common issue of RCA functionality. As mentioned previously, connectors are not simply parts of the electrical circuit; they are also mechanical structures. Their electrical properties and their success as part of the electrical circuit depends on how well the mechanical properties of their materials are suited for the intended function. The metal ground collar of the RCA (which is often an extension of the RCA body) is a large receptacle. It needs to have the ability to expand and retract, ensuring consistent pressure on the female socket, in order to maintain low contact resistance. Most of the metals used to create the ground collar of an RCA do not have the ability to retract. The result is after a few mating cycles, the contact resistance increases which starts becoming evident over the time. Contact manufacturers have addressed this issue by developing special contact profiles to improve the retraction ability of the ground collar and they have introduced alloys with more suitable mechanical properties. However, the locking function is the most efficient method to ensure a consistent, low resistance contact over a very long period of time and in wide range of situations where tolerance differences between the mating parts may occur. The locking function: The threaded shell of the connector screws onto the body of the RCA while gradually applying pressure onto the jaws of the ground collar, effectively acting as a clamp onto the RCA socket. Remember, the aim of the locking mechanism is to maintain low contact resistance, not to prevent the cable from being pulled out! Do not over-tighten the locking barrel. Not all locking RCAs have exactly the same design or use the same materials. So, there are slight variations on the way they function. Sometimes the outer barrel is a two part construction and sometimes a single piece. In some cases, the locking mechanism may require more force (i.e. when the ground collar is formed by thick brass plates), while in others a gentle rotation is sufficient (i.e. when the ground contact is formed from a softer material like pure copper or silver) In some cases, the ground jaws are relaxed enough to slide onto the socket without any resistance - when in the “open position” - and once the barrel is locked the jaws will clamp onto the socket. In other cases the jaws may offer adequate contact even when in “open position” and the locking barrel is simply used to adjust the pressure after an extended period of use, or when the repeated connecting/disconnecting has caused a relaxation of the jaws from their original condition. We offer a selection of locking RCA plugs to meet all budgets but always ensuring that they will perform to very high standards. Our aim is not to stick to appearances and brand names but to focus on the aspects that offer an advantage in terms of performance within a given price-range.

144Br/Au & 144Br/Ag - locking RCA connectors: These RCA connectors have a similar profile to the 1st Generation of WBT plugs who introduced the concept of the locking RCA. The entire body, barrel and pin is made of brass and the contacts are gold or silver plated.

Rhodium plated brass, locking RCAs, with hollow signal pin.

Rhodium plated locking RCA connector with carbon fiber layering. Very reliable and durable locking connectors with high EMI protection.

110Ag pure silver custom made locking RCAs.- NEW vers. The 110Ag are heavy duty, locking RCAs featuring a pure silver signal pin and a silver plated brass body with a matt black locking barre. The hollow signal contacts/pins of these RCAs are machined by ourselves from 99.99% pure, fine silver and the connectors are assembled in our workshop in Wales. The body of the connector is made of silver plated brass offering full shielding with a connection to the ground. The design of the connector body and locking barrel is based on the Furutech FP110 / FP108 RCA connectors and it features a reverse locking mechanism to maintain a firm ground contact. The 110Ag are fabricated on order with any of our handcrafted cable designs.

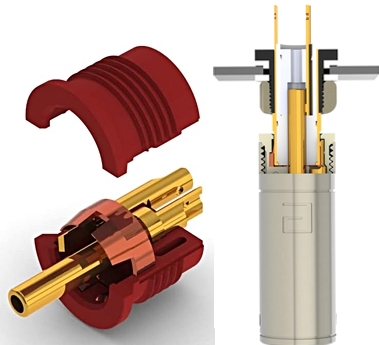

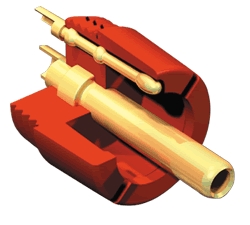

An introduction to single point ground RCA plugs - Eichmann / ETI Bullet plug. The single point ground design is the most important structural innovation that happened to RCA connectors since the 40s. It effectively replaced the metal, ground collar with a ground pin and reduced the overall active mass of the connector by up to of 90% The original bullet plug brought the most radical transformation of the traditional RCA connector design and it introduced it in the market with great success. The main elements of this design are nowadays featured on many connector products that are available from various manufacturers. The basic principle of the Eichmann Bullet is very simply but it is also a radical departure from the traditional RCA design. A typical RCA connector emulates a coaxial design. It has an outer ground collar which secures on the outer part of the RCA socket (effectively making contact on multiple points). In the case of the “Bullet plug” the ground collar and metal body of the traditional RCA has been replaced by a metal pin that makes contact on the outer part (signal ground) of the RCA socket on a single point. On the majority of the “single point ground” designs, the ground pin/contact is mechanically supported by the plastic insulation of the connector. According to the patents, the aim fo the “Bullet Plug” was to minimize the energy storage and reduce the inductive and capacitive effect of the connector on the signal by using an optimal ratio between the signal (send) and ground (return) conductors and by reducing the mass of the conductors/contacts. Furthermore, the “single point ground” design of the Bullet plug has also resulted to minimizing the Eddy currents at the part of contact with the mating sockets by reducing the contact area to a single point. Balancing the mass of the signal and ground contacts (control capacitance and inductance), and creating a single point ground (eliminating Eddy currents) are not the only benefits of the bullet plug. The lower metal mass of the connector meant that the choice of metals that could be used as conductors at affordable cost, is much wider. The use of pure silver and copper on both contacts and high quality types of plating is now possible at reasonable production costs; hence most single point ground RCAs tend to have a much better selection of materials. In addition to the overcoming the production cost related restrictions about using more expensive copper and silver in the place of brass alloys, the single point ground design enabled the use of such metals by addressing certain technical concerns. In their pure form, Copper and Silver are too soft to be be used on such applications. Even when hardened or as part of high conductivity alloys, they do not have the necessary mechanical characteristics required. The RCA ground contacts need to be able to combine a certain degree of flexibility, hardness and spring properties (typically found on phosphor bronze and beryllium copper alloys). On most single point ground bullet plugs, the lack of of some of these necessary mechanical properties of the metal are compensated by the use of the insulator which acts as a support structure for the low mass contact. I.e. although the pure copper pin may not be able to spring back on its own, the insulator which supports it (usually a type of nylon) forces it back into place, to allow a low resistance contact with the female socket after several mating cycles. Of course, since the introduction of the original Bullet Plug almost 20 years ago, the design has been adopted and further developed by many manufacturers. The initial collaboration between Keith Louis Eichmann and ETI that produced the Bullet plug has ended and currently KLE and ETI have their own separate lines of “Bullet Plugs”.

KLE Innovations Harmony Plugs More details on KLEI plugs here

Star-line RCAs More details on Star-Line RCAs here

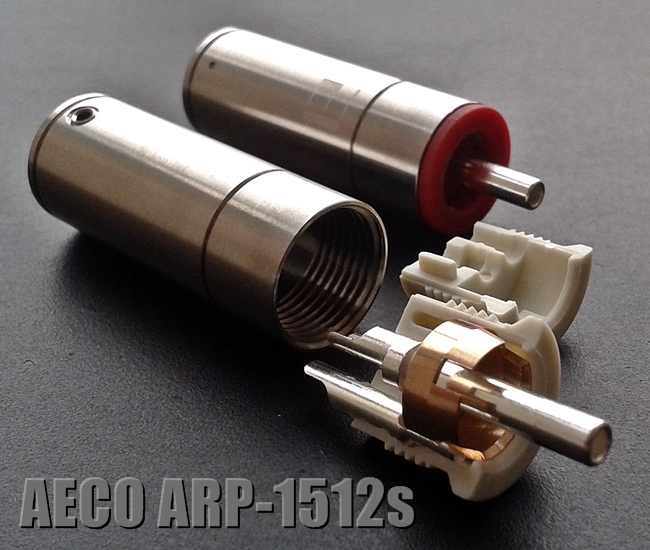

AECO ARP-1512 The ARP-1512 is one of the most recent single point ground designs by AECO. It provides an enhanced connector durability and firm mechanical contact with the use of a “floating” / isolated C-ring. The signal and ground contacts are made of high purity Tellurium Copper (C14500 with over 99% pure copper) and thick 10µ gold plating or 120µ silver plating without a nickel base.

Not all of the low mass phono plugs feature a single point ground design. Some connector designs have expanded the surface of the ground contact while maintaining the overall low mass. Using this approach they reduce the likelihood of contact failure (on a single pint) while ensuring a firm grip on the socket. The following are a couple of relative recent options for such low mass phono plugs: Viborg VR105:

WBT NextGen More details on WBT NextGen RCAs here

Furutech FT-111

In all honesty, we cannot tell you how a connector sounds. You may expect that a connector will have a certain, predetermined sonic signature as a result of being made of silver or copper, but we cannot endorse such an approach. We can only evaluate connectors in relation to their ability to minimize their impact on the signal quality based on their design, their materials, their mechanical, electrical & physical properties - over a period of time and in variable mating conditions. So, how is a great RCA connector defined? It is one that can achieve very low, consistent impedances, in a wide range of conditions and over a long period of time/large number of mating cycles. It is also one that has the ability to isolate the signal from the its surrounding / external environment. The selection of materials, tolerances, shape, profile and the overall structure, only have a meaning when they can contribute to the above aims. When one tries to evaluate the impact an RCA connector can have on the overall performance it is a good idea to keep the following in mind: - Most of the electrical properties of a cable assembly that have an impact on the quality of the analogue signal are proportionate to its length. The actual portion of the RCA connector that is used as “signal path” does not exceed the 2-3 cm (depending on the connector). - Due to the high mass of the RCA conductors (even of those that are considered “low mass” designs), the RCA connector -almost always- will exhibit lower resistance than the equivalent portion of the cable which is used on the interconnect assembly, regardless if it is made of silver, copper, brass or bronze. - Many RCA connector manufacturers tend to overemphasize on the fact that their products exhibit very low impedances. This may be true, but the properties of a connector should not be assessed by presenting it as a “stand alone part”. The performance of a connector is evaluated when it is in use (i.e. connected to the cable and the mating socket). It is important to understand that, due to the geometry of the RCA connection, the impedances during the operating state are primarily determined by the portion of the cable which is inserted in the plug and by the RCA socket; not by the plug itself. - The most critical parameter which has major implications on the performance of RCA connectors is the contact resistance. Most of the relevant contact research across various industries extensively focuses on the mechanical properties of the materials, their profiling and their surface finish in order to help minimize contact resistance. As mentioned above, we do not sell connectors, and we have no intention to steer our customers towards certain options. We simply want to offer an informed advice in order to help you with your decision. Personal experiences can be an invaluable source of information. However, they do not replace scientific knowledge. We are certain that many of you have used connectors that we would consider less than adequate, without having any issues with them after many years of use. Others may find that after a relatively short use, your connectors began to wear off or have a less than optimal performance. One should manage his/her expectations based on how the connectors are used. So, if you intend to frequently switch your cables among equipment or expect them to endure relatively “rough handling” choose your connectors accordingly. Some materials (both plastics and metals) may have excellent electrical properties. This does not mean that their mechanical characteristics are always up to the task. Overall the main conditions for any connector to perform at its best are to be free from wear and oxidization and have a firm contact on the mating socket. As a last point, we would like to mention that the RCA plug/socket - although it is the most common type of connector found on analogue Hi-Fi interconnect cables and equipment - it is one of the least suitable connector types for these applications. By design, the RCA connector has numerous drawbacks. And although certain alterations of the original RCA design have improved the overall performance potential, the RCA plug remains one of the least efficient options among the available connectors. It may be practical to use and easy to work with but there are far better connector designs provided by DIN, mini XLR and a wealth of miniature, pin based systems by companies like Lemo, Binder etc. Such alternatives would be more relevant to the specific application and more efficient in terms of their functionality than the best RCA connector could ever be. Unfortunately, our choices are limited by what the component manufacturers choose to offer as a connecting option on their products. And the vast majority of them choose to work with the RCA connectors that are universally recognizable and widely available.

NOTES ON THE CONNECTOR PLATING The main purpose of the plating on the connectors that are used for the low level audio signal is not to enhance the electrical properties of the base material or offer certain sonic attributes. Its primary aim is to protect the contact from mechanical and chemical wear while maintaining a good degree of conductivity. By doing so, it prevents a detrimental increase of the contact resistance in the longterm. The different types of plating have significant differences in regards to the above. When comparing the most popular ones (Silver, Gold & Rhodium) the silver plating has the highest conductivity and lowest wear resistance while Rhodium plating has the lowest conductivity with the highest wear resistance. So as you can see there is an obvious trade-off between mechanical/chemical degradation and electrical conductivity. One should be aware that Silver plating (although very popular) is likely to tarnish, wear off or allow the copper base material to creep on the surface leading to oxidization. The typical “tarnish” may not be of a major concern (since it can be easily removed similar to the pure silver contacts). However, the mechanical wear and the copper “creep” are permanent. There are many factors that can speed up these degradation processes (the plating process itself, the environmental conditions or the way of handling of the connector). On the other hand, gold platings are a lot more resistant (especially “hard plating”) and they are likely to last much longer than silver ones. Rhodium platings are not likely to experience any degradation for many years but they do so at the expense of exhibiting a lower degree of conductivity. There is not a perfect choice of plating, and the better choice always depends on your personal circumstances and they specific application. You can make your decision based on your experience and understanding of the concept. However, we would advise you to consider how a connector will perform in the long-term and not simply on the day you will receive your cables. The above notes address only a very basic consideration in regards to the connector plating. The topic is quite complex and requires an extensive discussion. There are various methods of plating using any/or a combination of the above materials and each method produces radically different results in regards to conductivity and mechanical or chemical resistance of the contact. We hope to create a separate section on this topic.

|

||||

|

High conductivity metals for connectors: Given that the analogue audio signal is an electrical signal, conductivity has always been one of the main considerations when choosing an electrical connector. Leaving cost aside, pure copper and fine silver (we use these terms assuming a minimum of 99.9% content of copper or silver) seem like a no brainier. But consider the following. Until 25 years ago, the use of pure copper and fine silver for electrical contacts like RCAs and XLRs was not even an option. The term “copper plug” was only used to refer to a copper alloy which has far lower conductivity than the pure copper that is used for the construction of wires for audio cables. Most male contacts (pins) are constructed using brass. A typical brass for a good quality plug would be a CuZn39Pb3 alloy which contains approx. 57% - 59% copper and has a conductivity of approx. 25% IACS (compared to a 102% IACS for a typical copper wire or 97% for a typical cold worked pure copper part/contact). Most female receptacles (i.e. female XLR contacts and in a some rare cases RCA ground collars) are made of Phonsphor bronze. The CuSn8 alloy is considered a common option for good quality contacts with good spring properties, it contains 92% copper and it has a conductivity of 13% IACS. Some alloys are often described in the connector promotional literature and manufacturer specs as “copper base”, “copper alloy” or simply “copper”. Yes, it is misleading and frustrating but in most cases one would have to use simple common sense to understand that pure copper cannot be practically used for connector parts that either require certain degree of hardness or a spring ability. Even today there is only a handful of commercially available pure copper RCA connectors: Notably the WBT NextGen Cu (not the older WBT versions from the 1st generation) and the Furutech FT111 (not any of their other RCA models). There are a few more connector manufacturers that use a pure copper signal pin but their ground contact is a copper alloy. Many well-regarded USA based manufacturers do claim pure copper RCAs but their connectors are predominantly copper alloys with OFC copper layering underneath the final plating. However, not all cases should be considered false claims.. There is quite an ambiguity as to what constitutes “Pure Copper” depending on the industry and the requirements; and given that impurities up to 0.7% are accepted in many industries for officially labeling a product as “Pure Copper” the process of identifying and specifying the base metal of a connector often leads to confusion. i.e. some Tellurium Copper alloys are often referred to as Pure Copper since they can have a content of Copper which is above 99% and conductivity above 90% IACS. Some Beryllium Copper alloys can contain up to 99.5% of Copper and they are also frequently referred to as Pure Copper despite the fact that their conductivity does not exceed the 40% IACS. Regardless, such alloys have so much better mechanical properties (hardness and elasticity) than Pure Copper and much better electrical performance than brass and Bronze alloys that make outstanding choices for electrical connector contacts. By just seeing the vast differences in conductivity between most copper alloys and pure copper we can understand the desire for any connector that is made of pure copper or silver. Recent design and manufacturing innovations have made the use of pure copper and silver possible for some types of connectors. However, caution is advised. Not all connectors that use pure copper and pure silver are necessarily better performers than copper alloyed connectors. Also, we should manage our expectations regarding the potential improvements in performance. The conductivity of the base metal of the connector is not the only (or even the main) defining factor for performance. When we put all things in context we can see that a copper alloyed connector is not necessarily such a bad choice. In many cases, the connectors that are used for low level analogue audio connections (i.e. RCA and XLR) have such a high mass and large cross sectional area (in comparison to the wires that are used to carry the signal inside the cable) that they entail no concern in regards to their ability to conduct the signal with extremely low resistance. Further more, when it comes to examining low level analogue signals, the conductor resistance is not the most concerning of the impedance that impact the quality of the signal. Concluding it is clear that choosing a pure copper or silver contact has some advantages but one should consider whether the additional cost using such connectors is likely to be balanced by the potential benefits.

|

||||

|

Yannis Tomé Audio Cables, 36 Dinas Terrace, Aberystwyth, Ceredigion, SY23 1BT, UK - email: info@back-promo.co.uk © 2025. Y. Tomé Audio Cables |

||||

.

.