|

||||||||

|

|

||||||||

|

Standard type, female tonearm connectors |

|||

|

1877Phono Tonearm connectors: Zavfino 1877Phono is a Canadian company which produces a variety of Hi-Fi audio equipment, parts and accessories. Although we have no affiliation with the company we have been using their tonearm connectors on our cables for over 15 years and they still remain our favourite tonearm connector option for any cable regardless its price range. They are not low cost options, but they are reasonably priced given their very high quality. They are produced at very tight tolerances and make use of materials that will ensure minimal impact on signal transfer. They are available in a few versions in order to accommodate all tonearms and set-ups We would gladly recommend these connectors without hesitation. |

|||

|

|

The 1877Phono tonearm connectors do stand out among most of the tonearm connectors in the market; even among some very high price offerings by very well regarded brands. By all means, if you think that they are within your budget, we would strongly recommend that you choose them as an option for your cables. To put it bluntly, what makes them far better connectors is not their appearance, their overall build quality and precise machining tolerances; It is their contacts. Using much better quality copper and creating a smooth but firm grip on the pins of the tonearm socket (without causing wear) is what makes the whole difference. The profiling of the contacts and the assembly method which allows free rotation eventually results to connector mating with minimal contact resistance. We understand that it seems like a small detail, (with not enough magic surrounding it), for such a price tag, but if there is some true benefit to be gained, this is where one should look into, |

|

More tonearm connector options: |

|

|

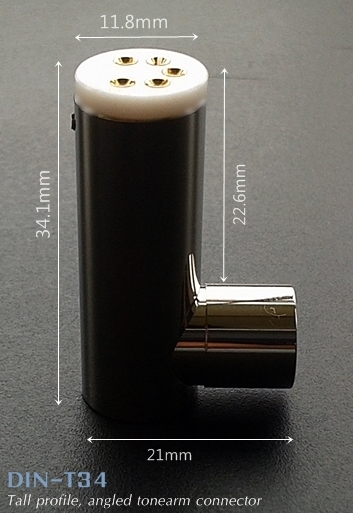

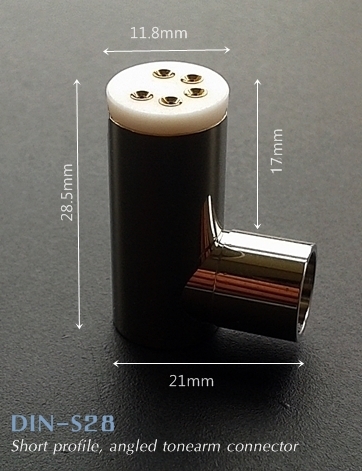

DIN-T34, DIN-M31 & DIN-S28 angled Tonearm connectors- Manufactured by AECO Angled tonearm connectors with a 2-part brass housing, Teflon insulation and 24K Gold plated contacts., These connectors are available with a variation of height in order to accommodate a very wide range of fitting requirements. The connectors have a diameter of 11.8mm making them also suitable for tonearms whose sockets are too narrow for the 12mm connectors. |

|

|

Furutech tonearm connector options: |

||||||||||||||||

|

||||||||||||||||

|

|

|||||||||||||||

|

The Furutech tonearm plugs are undoubtedly excellent connectors. They all feature rhodium plated, phosphor bronze contacts, Teflon insulation. Their stainless steel housings are machined and finished in the highest standards. Although they are high performing connectors we would also describe them as luxury products, and much of their high price reflects this appearance without necessarily adding further performance advantages. Also, note that these connectors are relatively large in size and they will require a good amount of clearance around the tonearm socket in order to be used without any issues. All of the above versions of the Furutech connectors can be available with our tonearm cables as an optional upgrade. |

||||||||||||||||

|

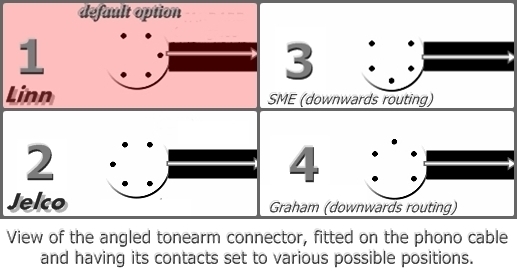

Tonearm connector basics: The 5pin tonearm connectors that are used on the majority of tonearms can often be a point of confusion when choosing a new tonearm cable. Although they are commonly referred to as “DIN” they are different from the standard type DIN connectors. Other common names used for them are JIS, TAC, Tiffany or mini DIN. Nowadays, the majority of tonearms that can accept a detachable external cable are fitted with a male, 5pin connector which is typically located at the base of the tonearm pillar. In some rare cases, (notably most of the Grace tonearms) may be fitted with the female output socket instead, hence requiring a male tonearm connector on the cable end. Of course, this type of tonearm connector, although it is used on the vast majority of tonearms, it is not the only type that you may come across. Some vintage tonearms may be fitted with 4, 5, or 7 pin standard DIN connectors or RCA connectors, while other, less common type of sockets can be found on some tonearms. In most cases, if you are the owner of such a tonearm, you will be able to tell by simply looking at the base of the tonearm pillar. There are also those tonearms that cannot accept a detachable external cable because they have captive leads (like Rega tonearms). Some others have their internal tonearm wires directly soldered onto an output socket (RCA or DIN) at the rear of the turntable. Choosing the right tonearm connector. Performance: All the standard tonearm connectors have the same layout and the majority of them uses Teflon as the dielectric material. As a result - unlike other types of connectors (i.e. RCA plugs) there can only be a very small performance difference resulting from the basic design of the tonearm connector. Often, when it comes to performance the focus is on the contact material. Most of the tonearm connectors use brass while in a few examples we come across the use of Tellurium copper or even pure copper in an effort to elevate the conducting ability of the contact. However, when it comes to the performance the most important factor is the contact resistance, and essentially the ability of the plug to make firm contact with the mating socket. There are many tonearm connector made of ideal materials in terms of their conductivity but they cannot achieve a good contact simply due to lack of tight production/design tolerances or due to the metals used not having the necessary mechanical properties. So,often a brass or phosphor bronze connector can be much better performer than a pure copper one. Installation: Most tonearms will be able to accept a standard, straight tonearm connector without any problem. However, the cable installation and fitting requirements are far from “universal”. They vary significantly depending on the make of tonearm, turntable, user set-up arrangement etc. The most obvious difference, is between a straight profile and an angled profile connector. A straight connector can be used when there is sufficient clearance underneath the tonearm pillar while an angled connector is preferred when there is limited clearance or when there is the requirement for a direct 90deg angle once the cable exits the tonearm pillar. If you choose an angled connector, you also need to make sure that the cable exits towards the desired direction. Tonearms have their sockets rotated in various ways, meaning that each case requires a specific connector choice. i.e. see image below.

Insertion depth. There is a small number of tonearm makes that have their sockets deeply recesses into their pillar (i.e. some Audio Technica, Audiocraft, Mayware Formula 4 etc). Or there are cases where the required insertion depth increases by using a tonearm base, or sleeve which extends below the tonearm pillar. In such cases, one should choose to use a tall tonearm connector which can be inserted deeply to reach the male socket inside the pillar. Connector diameter. the diameter of the tonearm connector is often overlooked, assuming that all tonearm connectors should fit all tonearms.This is not true. Tonearm connectors are typically produced with an insertable diameter between 11.7mm-12mm. Most tonearms will accommodate a diameter up to 12mm but not all. Some can only accept a maximum of 11.9mm or 11.8mm and given the very small difference it is often difficult to tell. in advance. We do stock quite a large range of tonearm connectors so that we can meet the requirements for different types of fitting at different budgets. However, having in mind the above, the tonearm connectors offered by 1877Phono are by far the best connector option in the market. They have an outstanding selection of materials, produced in tight tolerances and offer a firm contact with the socket. Their profile allows them to be fitted in all types of tonearms while the three versions that we have in stock cover most of the fitting requirements (standard straight, anngled and tall straight). We are not affiliated in any way with Zavfino 1877Phono but we have been using these specific connectors for 15 years and we cannot recommend anything that would outperform them. Unfortunately, their price has risen significantly in the last few years and they cannot be considered an economical option. However, they are still significantly more reasonably priced than most well-known brands like Cardas, SME or Furutech, while their performance meets the top standards of the market. |

||||||||||||||||

|

Yannis Tomé Audio Cables, 36 Dinas Terrace, Aberystwyth, Ceredigion, SY23 1BT, UK - email: info@back-promo.co.uk © 2025. Y. Tomé Audio Cables |

||||||||||||||||